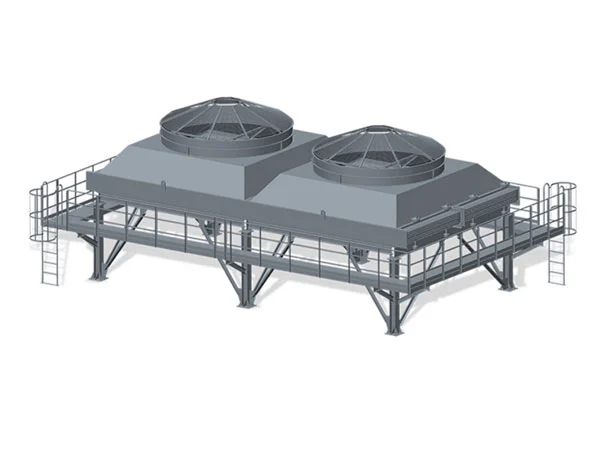

Energy Efficiency: Industrial air cooling systems are designed to be more energy-efficient compared to other cooling systems. This is because they use less power to cool the air, and they have a lower energy consumption for running compressors and fans.

Reduced Environmental Impact: Industrial air cooling systems often use refrigerants that have lower global warming potential and reduced ozone depletion potential, which makes them a more environmentally friendly option.

Reduced Operating Costs: The lower energy consumption of industrial air cooling systems translates to lower operating costs compared to other cooling systems. They have low installation and maintenance costs, making them an affordable solution.

Improved System Reliability and Performance: Industrial air cooling systems are more reliable and high-performing compared to traditional cooling systems. They can maintain a consistent temperature that meets the requirements of industrial processes, which helps to avoid damage to equipment and improve overall efficiency.

Lower Maintenance Requirements: Industrial air cooling systems usually have fewer moving parts than other cooling systems, which reduces the maintenance costs and requirements. Regular maintenance is still essential, but it is easier and more cost-effective to carry out.

- Home

-

Products

Vibration-Damping Fasteners Upper Self-locking (Third Generation) Double-layer Non-linear Vibration Damping Fasteners Double-Layer Nonlinear Vibration Reduction Fastener With Shoulders FST Type High Torsion Resistance High Vibration Damping Turnout Vibration Damping Fastener Rail DamperSynthetic Rail SleeperApplication Semiconductor Display and Semiconductor Integrated Circuit Solar Photovoltaic, Sapphire, MOCVD Equipment, Medical CT Equipment, High-temperature Heating Furnace and Other Industries Molybdenum Material Deep Processing, Steelmaking and Other Industries New Energy, Rare Earth Permanent Magnet, Structural Ceramics, NdFeB Vacuum Equipment Industry

-

Application

ApplicationApplication Fields of New Electronic Materials

- Semiconductor Display and Semiconductor Integrated Circuit

- Solar Photovoltaic, Sapphire, MOCVD Equipment, Medical CT Equipment, High-temperature Heating Furnace and Other Industries

- Molybdenum Material Deep Processing, Steelmaking and Other Industries

- New Energy, Rare Earth Permanent Magnet, Structural Ceramics, NdFeB Vacuum Equipment Industry

- About Us

- Branches

- Contact Us

- News

EN

EN