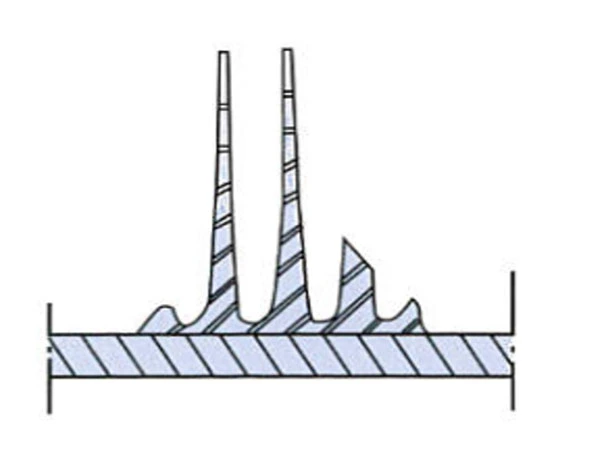

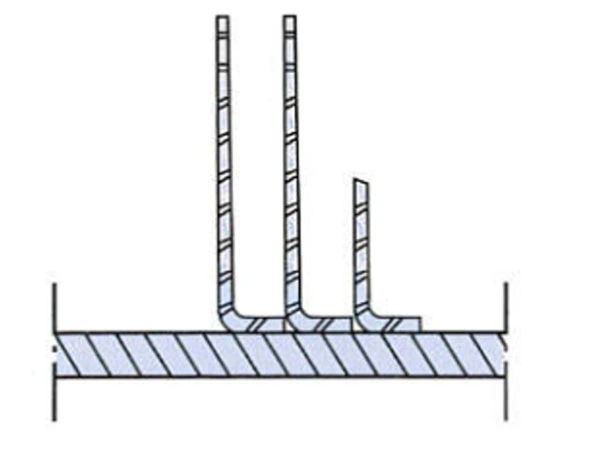

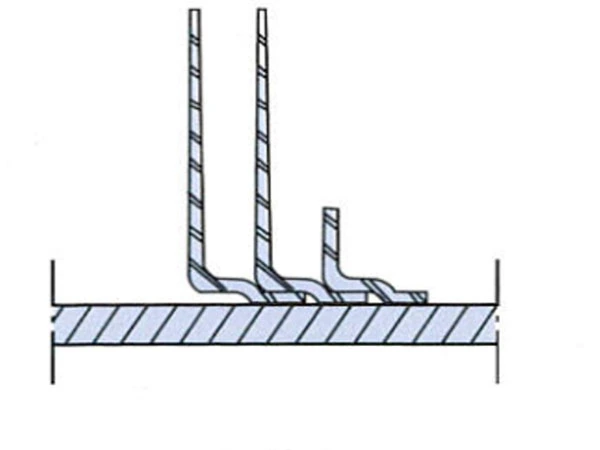

The KL Fin Tube, also known as the "Knurled L" Foot Fin Tube, is the latest and most commonly used type of wrap-around Fin Tube. KL Type finned tubes are a specific type of finned tubes that feature a unique KL-shaped fin design. The fins are attached to the outer surface of the tube, forming continuous KL-shaped profiles along its length.

KL Type finned tubes find applications in various industries, including power generation, petrochemical, and HVAC systems. They are commonly used in heat exchangers, air coolers, and condensers, where optimal heat transfer is critical.

Currently, it is one of the most popular and preferred choices in the industry. This particular type of Fin Tube is manufactured using a process similar to that of the 'L' Fin Tube. However, in this case, the Tube is knurled, creating a textured surface, and simultaneously, the 'L' base of the fin stock is also knurled. This knurling process ensures a firm bond and significantly improves the contact between the Fin and the Tube.

EN

EN