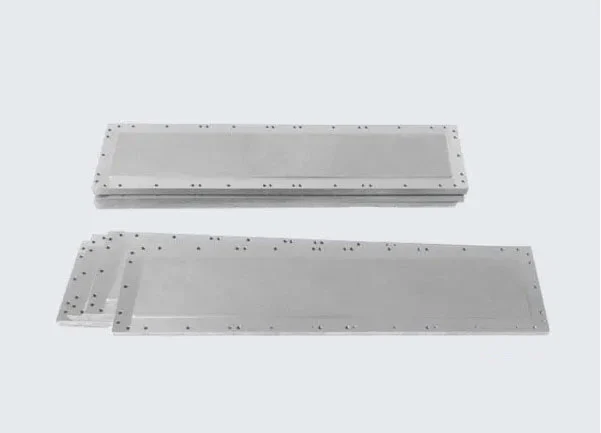

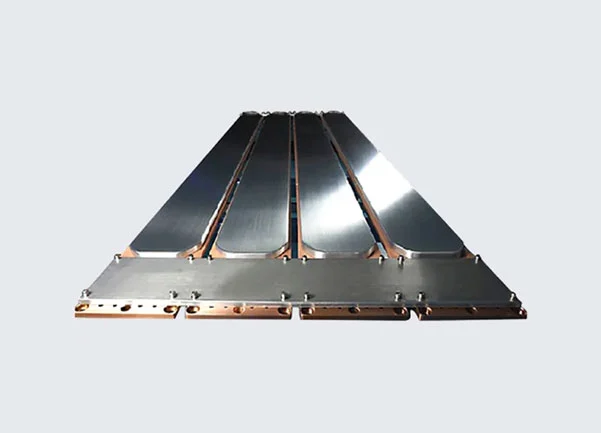

Molybdenum alloy targets are widely used in thin film coating applications due to their unique properties. One of the key advantages of molybdenum alloy targets is their high melting point, which allows them to withstand high temperatures during thin film deposition processes. This makes them ideal for use in high-temperature deposition techniques such as physical vapor deposition (PVD) and chemical vapor deposition (CVD).

Molybdenum alloy targets also have good corrosion resistance, making them suitable for use in harsh chemical environments. Additionally, they exhibit good thermal and electrical conductivity, which can help to improve the performance of thin films in electronic applications.

Another important property of molybdenum alloy targets is their high density, which allows for a high deposition rate with good film uniformity. This is valuable in applications where a highly uniform and consistent thin film is required.

Molybdenum alloy targets can also be successfully surface modified using various techniques such as ion bombardment, plasma treatment, and coating deposition, which can further enhance their properties for thin film coating applications.

Overall, molybdenum alloy targets offer a range of properties that make them well-suited for use in thin film coating applications, particularly those involving high-temperature deposition and harsh chemical environments.

EN

EN