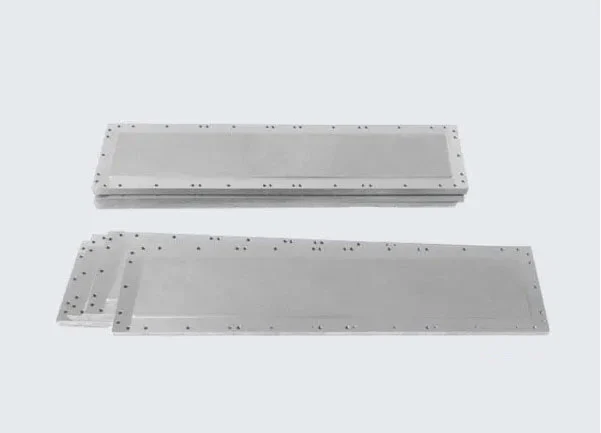

Titanium-aluminum targets are a critical component of thin-film deposition processes in many industrial applications. The properties and advantages of titanium-aluminum targets stem from the unique properties of titanium and aluminum, which combine to create materials with high strength, excellent corrosion resistance, and lightweight.

One of the primary benefits of titanium-aluminum targets is that they have high sputtering rates, which make them suitable for use in high-throughput sputtering processes such as magnetron sputtering. These processes result in high-quality, uniform coatings that exhibit excellent mechanical and chemical properties.

Titanium-aluminum targets are also highly resistant to corrosion, which makes them suitable for use in harsh environments. The corrosion resistance of titanium-aluminum targets is due to the formation of a protective oxide layer on the surface of the target, which prevents further oxidation.

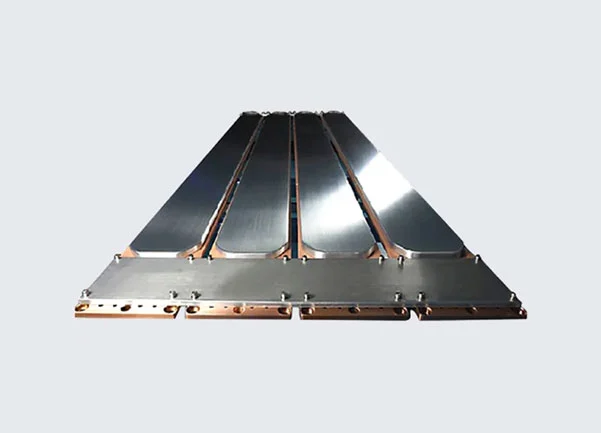

Additionally, titanium-aluminum targets exhibit good thermal conductivity and low thermal expansion, which make them particularly well-suited for use in high-temperature applications such as aerospace and aircraft components.

Overall, the benefits of titanium-aluminum targets include excellent mechanical and chemical properties, high sputtering rates, resistance to corrosion, and thermal stability. These properties make them valuable for use in many industrial applications, including aerospace, automotive, and medical devices.

EN

EN